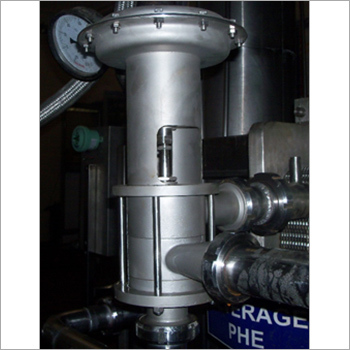

Pneumatic Modulating Valve

Pneumatic Modulating Valve Specification

- Valve Size

- DN15 to DN300

- Material

- Cast iron/SS316/SS304

- Control System

- Pneumatic actuator with positioner

- Connection Type

- Flanged, screwed, or welded

- Valve Type

- Modulating globe valve

- Features

- Precise flow regulation, leak-proof seating, corrosion resistance

- Application

- Flow control in HVAC, process industries, water treatment, and chemical plants

- Structure

- Two-way globe type

- Sealing

- PTFE/EPDM

- Voltage

- Not applicable (pneumatic control)

- Type

- Modulating pneumatic valve

- Power

- Pneumatic actuation

- Pressure

- Up to 10 bar

- Media

- Water, steam, air, gas, oil

- Port Size

- 1/2 inch to 12 inch

- Temperature

- -10C to 180C

- Disc

- Stainless steel

- Pin

- Stainless steel stem

- Body Coating

- Epoxy coated for corrosion protection

- End Connection Standard

- ANSI, DIN, JIS, BS

- Shut-Off Class

- Class IV and V (Optional)

- Actuator Type

- Single acting/Double acting pneumatic cylinder

- Position Feedback

- Available with 4-20 mA position transmitters

- Mounting Orientation

- Universal, horizontal or vertical

- Packing

- Graphite/ PTFE for stem sealing

- Compliance

- Conforms to ISO, API, and EN standards

Pneumatic Modulating Valve Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 1 Week

About Pneumatic Modulating Valve

Food Craft Technologies deals in the manufacturing and supplying of best-in-class Pneumatic Modulating Valve which is designed by using top grade alloyed carbon steel which results in higher strength and sturdiness that makes it capable to resist large impact forces and pressures. This air and gas control industrial equipment is also provided an analog type measuring dial which is used to give the measure of fluid pressure within the system for the safe working. Buyers can get this heavy-duty Pneumatic Modulating Valve from us as per their demands at a reasonable price range.

Shutter equal percentage:

In a shutter with equal percentage characteristic, every increment of stroke in the shutter produce a change in the flow that is proportional to the one that flowed before the change.

Gaskets are used isopercentual valves for:

Fast processes.

When the system dynamics are not well understood.

Globe Valve

Valve whose construction is distinguished by controlling the flow through a linear movement.Valve with single seat and 2 ways.

Single seat valves require a larger actuator for closing the shutter against the differential pressure of the process.

The tight closure is achieved with stainless steel shutter and PPL seat.

Normally Closed Control Valves (Spring Return)

Drive: pneumatic (air to open)

Features:

- Body material: SS304, SS316 (Made out of solid stock for robust structure)

- Connection: Flanged ends, threaded, SMS Union, Triclover

- Limit of pressure: Water 16 bar at 120ºC

- Steam 13 bar at 200ºC

- Working Temperature: -20ºC / + 230ºC

- Diaphragm type, spring return, normal close.

- Maximum input pressure: 10 bar.

Versatile Engineering for Diverse Applications

This modulating pneumatic valve is designed to serve a broad range of industries, including HVAC, water treatment plants, chemical manufacturing, and various process sectors. Its adaptable configurations and end connection standards make it suitable for different installation requirements, ensuring compatibility and ease of integration for both new and existing piping systems.

Precision and Reliability in Flow Control

With features such as a pneumatic cylinder actuator, position feedback via 4-20 mA transmitters, and highly corrosion-resistant construction, this valve guarantees consistent modulation and control. It supports shut-off classes IV and V for tight sealing, while graphite or PTFE packing delivers exceptional stem sealing. The universal mounting orientation allows installation flexibility as per site demands.

FAQ's of Pneumatic Modulating Valve:

Q: How does the position feedback system work in this pneumatic modulating valve?

A: The position feedback provides real-time valve position information through a 4-20 mA transmitter, ensuring precise monitoring and control over flow regulation in automation systems.Q: What are the main benefits of using this valve in industrial applications?

A: This valve offers precise flow modulation, robust corrosion resistance, leak-proof seating, universal mounting, and minimal maintenance due to its high-quality materials and epoxy coating.Q: When should I opt for single acting versus double acting actuators?

A: Single acting actuators are ideal for fail-safe applications where the valve must return to a default position on air failure, while double acting actuators are preferred for rapid and consistent actuation in both directions.Q: Where can this valve be installed within process systems?

A: This valve supports universal mounting and can be installed horizontally or vertically in a variety of pipelines, serving as a control component for water, steam, air, gas, or oil media.Q: What is the process for selecting the correct port size and end connection?

A: Port size and end connection are selected based on flow requirements, system pressure, and the pipeline standards (ANSI, DIN, JIS, BS) inherent to your facility's specifications.Q: How does the epoxy body coating contribute to the valve's performance?

A: The epoxy coating provides exceptional corrosion protection, extending the valve's operational life, especially in chemically aggressive or moisture-prone environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS