Silo Weighing System

MOQ : 1 Unit

Silo Weighing System Specification

- Function

- Automatic Weight Measurement

- Battery Life

- Optional up to 8 hours (UPS)

- Features

- High Precision, Rugged Construction, Easy Installation, Overload Protection

- Display Type

- Digital

- Application

- Bulk Material Storage Silos

- Power Source

- Electrical

- Connectivity Type

- Wired/Ethernet

- Size

- Custom as per Silo Size

- Interface

- RS-232/RS-485

- Automatic Grade

- Automatic

- IP Rating

- IP65

- Usage

- Industrial, Process Automation

- Product Type

- Silo Weighing System

- Weighing Scale Type

- Tank/Silo Hopper Weighing System

- Material

- Mild Steel/Stainless Steel

- Power Supply

- 230V AC, 50Hz

- Monitor Display

- Digital LCD/LED

- Load

- Up to 60 Ton

- Accuracy

- 0.05% of full scale

- Capacity Range

- 5 Ton to 100 Ton

- Color

- Industrial Grey

Silo Weighing System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 3 Week

About Silo Weighing System

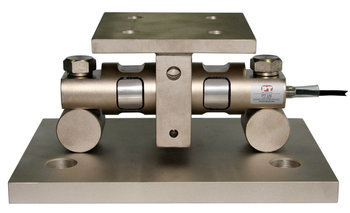

Silo Weighing System manufactured and supplied by us is designed for the load measurement of large tanks and vertically oriented storage silos. It is equipped with a high-performance load cells fixed in between two flat metal plates. The weight measuring unit of this device is connected to a highly calibrated electronic system to give highly accurate results. The base plate of the offered Silo Weighing System is provided with a series of holes to makes tight and rigid connections with the help of mechanical fasteners for higher stability and rigidity.

Precision Engineering for Efficient Bulk Storage

This Silo Weighing System combines advanced technology with robust engineering to deliver accurate measurements under challenging industrial conditions. High-precision load cells and automatic digital calibration maximize reliability, minimizing errors and manual involvement. Its versatile compatibility with compression/shear beam mounting and customizable scaling options adapt seamlessly to varying silo sizes and capacities, ensuring optimal performance for large-scale material management.

Integrated Control & Seamless Automation

The built-in PLC/HMI control panel facilitates centralized monitoring and management of silo hoppers. With analog (4-20mA) and digital outputs, as well as RS-232/RS-485/Ethernet connectivity, real-time data integration with existing process automation systems is straightforward. The digital LCD/LED display provides clear weight readouts, while built-in alarms for overload and faults enhance operational safety and responsiveness.

FAQ's of Silo Weighing System:

Q: How is the silo weighing system installed with different mounting types?

A: The system utilizes compression or shear beam load cells, mounted securely under or alongside the silo base. Installation is designed for simplicity and adaptability, with custom sizing to match the specific silo structure and capacity requirements.Q: What process is involved in calibrating the silo weighing system?

A: Digital auto-calibration is a key feature. Once installed, the system can be calibrated electronically via the PLC/HMI, ensuring accurate weight readings without manual adjustments. This streamlines setup and enhances task efficiency.Q: When should maintenance or recalibration of the silo weighing system be performed?

A: Routine system checks are recommended every 6 to 12 months, depending on operational intensity. The automatic calibration function minimizes maintenance needs, but periodic validation of load cell accuracy and enclosure integrity is advised for optimal performance.Q: Where can the silo weighing system be used?

A: Designed for industrial environments, this system is ideal for bulk material storage silos in manufacturing plants, warehouses, and processing facilities across India. The weatherproof enclosure (IP65) allows safe outdoor or indoor usage, even in high-humidity conditions.Q: What are the benefits of having data logging and alarm systems integrated?

A: Data logging enables secure storage and easy retrieval of weight records via USB or SD card, supporting inventory management and compliance. The built-in alarm system promptly notifies operators of overloads or faults, improving safety and minimizing downtime.Q: How does the weighing system interface with automation and monitoring networks?

A: It supports analog and digital outputs alongside RS-232/RS-485 and wired Ethernet interfaces, allowing seamless integration with process automation and remote monitoring systems. The digital LCD/LED display offers instant access to real-time weight information.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS